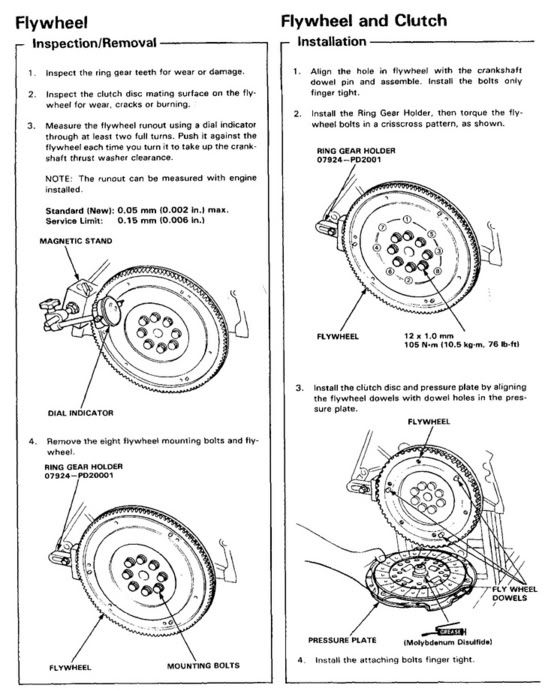

how do i prevent the flywheel from spinning while torquing it? the haynes manual gives the part number for the tool that holds it in place, but the palces i went to dont know what it is. one place i went to have it, but it didnt work like it said it would(was actually made for turning it).

if anybody knows where i can get the tool from(preferably a place in canada), or how to prevent the flywheel from turning while im torquing the bolts, it would be greatly appreciated

Reply With Quote

Reply With Quote

Bookmarks