now you just need to make another one for that civic accord hyundai dude. forget that build him a car with a flux capacitor so he can go back and unabuse it.

now you just need to make another one for that civic accord hyundai dude. forget that build him a car with a flux capacitor so he can go back and unabuse it.

1989 Honda Accord LX-i

B18c1 swap since 7/2011

175whp and 132tq

Redzone tuned

lookin good tim. i wish i had access to a machine shop. i'll probably take the machine shop class next year. looks like it would be quite helpful to have those skills.

Keep it HONDA. Or at least Asian.™

*Weber 32/36*Pacesetter Header*2.25 in. Cat Back exhaust*SE-i rear disk brakes

B18C swap ditched, A20 to be revived

Looking for K20/trans for ultimate swap

Another couple of small but important projects. first,the hose for the pcv valve. thats a stainless steel spring on it,that keeps it from collapsing. the pcv valve is screwed right into the manifold. honda could have taken a design lesson on that one. instead of sticking it in the middle of a failure prone hose. you need to keep the pcv system,because it makes a huge difference in cutting down on engine sludge. i am redesigning the oil seperator part of it though,especially the part where the hose connects to the oil pan. it always leaks there,and the hose rots out from oil collected in it. i am going to all threaded fittings,and AN braided hose. no more hose clamps on the pan. i am using a morrosso oil seperator filter and making my own housing. the entire seperator from morosso is like eighty bucks,but the filter from inside is only around 12 bucks. screw that,i'll make my own to my specs. it takes a -16 hose from the pan to the seperator. thats a big hose because it cuts down on the air velocity flowing out of the pan,and sucks up less oil. it takes a big hose all the way to the pcv valve,the pcv valve regulates vaccume to the pan.

PCV valve

you can see how once the hose is clamped it clears the center linkage

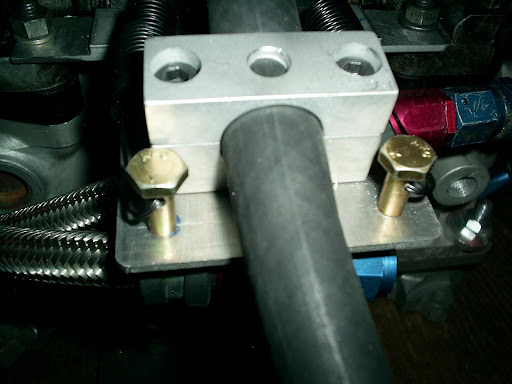

clamp for the hose,this is really important on here,since if the hose was loose it could interfere with the throttle linkage,and possibly hang the throttle open. it's two pieces,the bolts go all the way through,then have nuts on the bottom,then the hose clamps atttach to the remainder of the threads,with spacers,and another set of nuts.

as to the previous post,they are stainless steel bowls,or at least they were.

a little more work on the carbs, I am at the point where i really need to find a junk engine, i have to finish up the bracing that holds up the back of the manifold,and helps keep the welds from cracking.

i need to make a steel plate that bolts,to the existing four bolt holes on the block.

in order to do this, i have to bolt the plate to a block,with the manifold and carbs attached to the heads,then fit the suport tubes to the plate,and weld them on.

plus i have lines and brackets to make. i figured i would just put the engine in my trailer, and weld up the stuff with it in the trailer.

here is the plate that is welded to the manifold. i ended up using three of the holes. they are tapped to 5/16-18

here you can see the bracing

the manifold will be braced to the block,just like the original manifold

i will get some better pictures later

I drove 212 miles to see this beauty

[IMG][/IMG]

Lostforawhile's done some amazing work putting together this manifold for SU carbs, I was pretty overwhelmed at the foresight put into it, working dual choke controller, oem carb linkage used, very functional air filtration, very nice machine and welding

[IMG][/IMG]

[IMG][/IMG]

[IMG][/IMG]

[IMG][/IMG]

flash ow. must feel good to make ur own manifolds and stuff

slap it on already

1989 Honda Accord LX-i

B18c1 swap since 7/2011

175whp and 132tq

Redzone tuned

look at that weld bead. ....stack 'o nickels anyone?

Looks great Tim. Let's get those bastards on and running.

Guy, now how 'bout making the 1200 mi. drive up to CT to help me w/ mine?

-Mark D.

i didn't do that weld,my step brother is an engineer in a company that makes heavy duty aluminum awnings for high rises, i had to send it to atlanta,took several hundred amps and a water cooled tig torch to do that one. we don't have anything at work that heavy. i wish we did

Bookmarks