Originally Posted by

Kelvin

You didn't read what I wrote, or what Carroll Smith wrote. It isn't BRAKING that causes it, it's UNEVEN PAD DEPOSITS. I'll talk you through it, one more time.

1. You install crappy pads with a low max operating temp.

2. You properly bed the pads, putting a smooth even layer of pad material on the rotor.

3. You are driving 'spiritedly' and get your brakes pretty hot, and come to a stop, or just slow down enough to transfer even more pad material 'unevenly'.

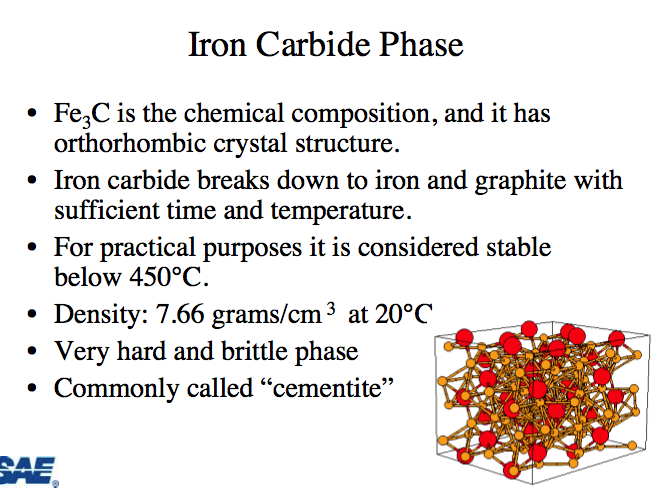

4. This 'uneven pad deposit' is thicker than the rest of the pad material on the rotor. Now, if this 'deposit' hits your pads on every revolution, it does NOT REQUIRE BRAKING TO CREATE HEAT. Driving on the freeway will lightly hit that 'thick' pad deposit on your existing pad with every revolution, creating MASSIVE amounts of heat in very localized regions of the rotor, right on the surface of the rotor, right under the pad material. It is this area that will create cementite.

Originally Posted by guyhatesmycar

:

:  it's a joke , man

it's a joke , man

Bookmarks