Ryan with your CR I would try 1 step colder..

Ryan with your CR I would try 1 step colder..

I would also try the Bosch resistorless plugs as well might make a bit of difference having all the spark you can get never hurts! lol!

alright guys, I had an idea. I've got an a20 head in pretty good shape with valves, Money is tight right now, and of course the damn snow is pilled up around here with the temps in the sub teens range right now. Would it help if i ported and polished the head myself, had the head milled flat (in case it isnt right now) and had the valve seats cut in for the a20 valves in the et2 head. You think that would help some? Are the valves in the a20 larger than the valves in the et2? I have literally full A20 valve train. Everything else in the current head is new, including the valve guides. Are the valve guides and valves different in the two heads that might keep it from being an easy cut in installation? I guess the catch is, I'll have to wait till January to really get the car running again, oppose to getting a new head gasket, and putting it all back together...

Only differences between the two heads are the valve springs and some of the retainers, but as you have new bisi springs and retainers for those you can just swap em straight over, or you could use your old ET2 ones which tbh are more than up for the job anyways the Bisi ones maybe a tad too stiff which could be loosing you a couple bhp from frictional loses!! I'd leave the A20 valves in just lap the seats in gently, if you can back cut the valves a little to match as they don't from stock, bit of port work, maybe new bronze guides from SI which are dirt cheap and not expensive to fit if you gonna have it machine flat, I'd maybe have the head crack checked first unless you 100% sure it was ok in first place, maybe take 1-1.5mm off it to raise CR ratio, trouble is you'll have to get another inlet manifold from South Africa to fit webers on or go downdraught with A20 inlet manifold. Just get the head off first all you may need is a small head skim and a new gasket. But it helps to have a backup plan just in case!!

i'd keep my et2 head, i was just curious if the valves were bigger in the si head vs the et2 head. unfortunately I can't just swap the head over, the et2 motor i have has the odd block. only this head will work with my block. makes it a pain in the ass to get head gaskets because i have to get the right one.

my head...

a18a1

a20

All the A20/A18/ET valves are the same, so no help there. I think the best thing to do is to pull the ET head and check it over really well to figure out what's going on. If it's cracked (and it very well could be) then you need another head, no getting around it. If it's not cracked then next is to figure out what went wrong. Warped head maybe? Block flatness out of spec? Crud or something got under the head gasket during installation? Until you pull it off this is all just speculation. If you find the problem was something simple like the head is out of spec for flatness, then I would just get it skimmed and put it back together for the time being until you have more cash to throw at it.

C|

Guys, don't forget car was running a little hot... I think, hope, it's just gasket issue..

Why was it running hot? I don't recall this? A webered engine with mods certainly wouldn't give you any temp worries with a good condition radiator.

Hey rich, Yea, it started this silly thing where it overheated on up to 240~250 degrees while I had a 1.3 bar rad cap on about 6/7 times. I would literally only touched it and stay up there for less than a min, and would cool back down to 180~200. I added an overflow tank and then i overheated maybe twice after that, then i put my 1.1 bar cap on and no problems at all. but by then it was too late... I'm convinced the head isn't cracked do to the fact that it had a small amount of antifreeze in all 4 cylinders. Seems like if it was cracked you'd see a more isolated amount between cylinders'

Yeah unlikely unless it was detonating and it's put a crack into each cylinder which I have seen! lol! but it's unlikely hopefully you just buggered up the gasket take it you not been able to whip it off yet!

not yet, depending on the weather tomorrow, i may pull that little bastard up in the driveway and possibly pull the head off, but i doubt it. Mostly cause I won't be able to get anything done on it. After reading multiple threads about the head design and shaping of the combustion chambers on these little things, i figure i might have the head milled all the the way down. I have basically been following Smeado and Cygnus all around the intrawebz. The whole discussion about deshrouding and shaping to mate to the head gasket, it seems that when cyg took 2mm off the head (which i believe is past the "service" point) the head looked the best it could look. I think I will take it to the service point (maybe more if cyg thinks its ok?) and further deshroud the exhaust side. I'm also going to do a DIY port and polish job on this head too. This is going to be my learner head. I want to get to 150whp at altitude!!! Any thoughts for most power on the ultra cheap?

nos? cheap.. lol

also, you bringing any of your many cars to my meet??

I'm coming out but I have a work Christmas party till 7:30. So ill probably have to text you to find you. White prelude or accord. Preference?

While you *can* take up to 2mm off the head, you may not want to in your case. Considering that your pistons are domed you may run into clearance problems, not just with the valves but with the pistons hitting the head itself. Also, adjusting your comp. test numbers for sea level gets them up around 200PSI, which is pretty good (nominal for that engine is about 155PSI). Milling the head much more may bump the compression up to where you can't run pump gas. Obviously if you don't mind running race gas then go right ahead.

Other head work is of course good. Deshrouding the valves will help flow. Polishing the combustion chambers as much as possible will help keep the heat in the chamber and reduce carbon buildup. Same for the exhaust ports. Keep the intake ports somewhat rough. Flare the intake ports a bit to eliminate any flow restrictions. Leave the manifold outlets untouched so there is a small step up in diameter at the transition to the head. The step helps reduce flow reversion. That's all I can think of to do for cheap.

C|

Ryan, E85 cross your mind yet? Pretty available to us

Bigger valves! lol!

I wouldn't go 2mm try 1.5mm and then you have a little reserve for another head off moment. Are you running filters on the webers? maybe try some shorter trumpets and leaving them breathing open air!!

Think you'll see quite a nice bump with a CR increase and port work could well be as much as 15-20bhp more with larger valves that are back cut and matched to decent seats.

I'm worried more about E85 going through my carbies. I hearing that it will require much larger jets (which is fine) and has some corrison properties when mixed with Aluminum...

Cygnus... here is a reminder of my piston protrusions from the block...

with head gasket...

thought this would be funny...

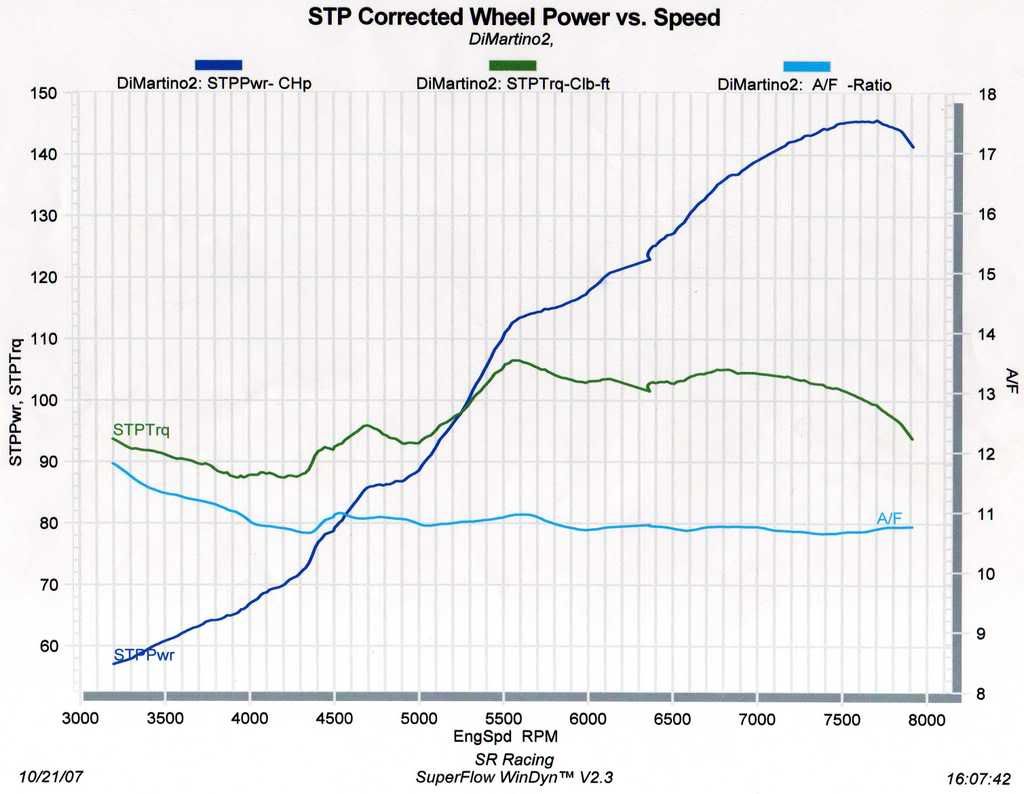

the dyno from my ill tuned white prelude from years ago!

Holy rich b16!!

Didn't thing about the aluminum in carbs.. I know a lot of old muscle cars doing it though

Looks like it should be fine with 1.5mm or 2mm off the head, that's going to be some holy serious CR ratio afterwards! I think the head gasket may struggle to hold CR ratio that high, do you know what it is at the moment? I'm guessing probably something around the 11:1 mark?

Where did you get your Felpro head gasket from? Those ones are really hard to find now if you can get some more like the one in the pics let me know I would like a few only have a 1 spare left and makes my ET1 head pretty useless to me now. Unless I can persuade you to buy a nice ported and flowed high CR ratio ET1 head from me! lol! Comes with Weber manifold too! ;0)

I thought felpro was the only thing available to us? That's the only thing I was able to get...

Oh, btw bring the white lude! And the slow!!

I wish I could bring 2 cars this weekend, but still so, i've got the uber common ignition wiring failure on the slow! Gotta replace it before I'm out driving it again. On top of the two car deal, Ali has to work friday night (she typically leaves at 9) so i'll be driving more than likely the White Prelude! I need to clean the outside up alot! It's so dirty from all the Mag Chloride! Either way, i'll be out and trying to find you guys after being full of Texas de Brazil!

I know you are in the middle of head work, but what are you going to do about the fuel spill in the chambers? It went full on rich! seems like the jetting is way off. school me, carbs are not my thing.

un-motivated!

someone make me an offer i just could not say no to.

3GR

hey 89T, I'm not sure what you mean about the full spill in the chambers... but my jetting isn't too bad. I was running about 13:1 afr at 6+k. I think the stuff i was talking about might have been a little residual from the antifreeze mixing with the fuel from the float bowls/ accel pump jets. I did my tests at full throttle (pedal to the floor) and when you pump the pedal there is a pump jet that adds a shot of gas for VE issues. In my case, its quite a bit of fuel, enough to foul out some plugs quiet quickly. (These massive pump jets help with partial to full throttle lean conditions. When the carbs go from partial to full you get a massive drop in the air speed in the throats therefor drawing less fuel from the float bowl via the idle/main jets, so the accel pump jets make up for that lack of fuel while the air speed catches up...) I'm guessing thats what your talking about...

Bookmarks