She sounded really healthy last night!!!

She sounded really healthy last night!!!

Thanks buddy, the cars running pretty good today! love the carbs... and the choke has made starting the car so much easier lately!

Alright guys, first things first...

I redyno'd at a really awesome shop to see if the power increased at all after retorquing the headgasket... The results were pretty close with a 5whp increase and damn near the exact same torque. So here are the videos...

watch for flame action between shifts...

Then I started this LONG over due Project...

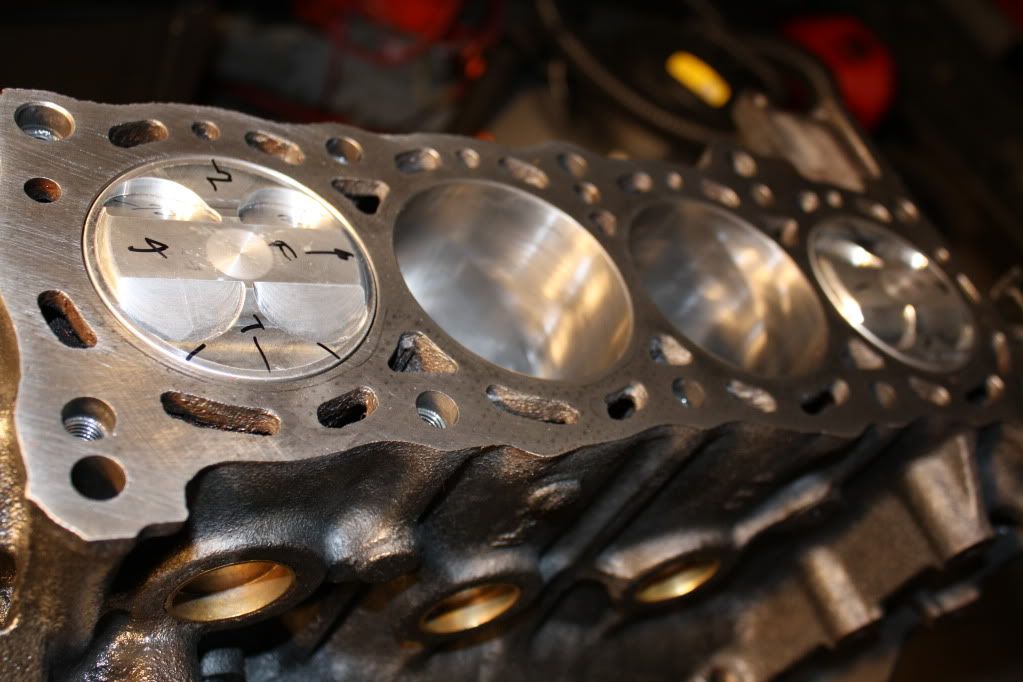

Pulled the head and time for a head gasket change...

But... before the head goes back onto the car...

Valves out...

...

...

Stock...

3.3mm!!! WooT!

Pretty much done with just one cylinder intake, unless someone has something they think i should add... I cut it all down with 80grit drums via the dremel. That to rough for my final cut, should I follow everything up with something finer for the Intake??? I figured the intake needs to be a little rough (although its feeling pretty smooth)

I was going to use the 80 to cut down the exhaust then finish it with 120, and final touch ups with a 320... This also a bad idea??? Then I'm going to open up the cylinders alittle bit more or so around the exhaust valve... Comments? Suggestions? This btw is my First time doing this... any help would be great

The extra 5whp could be the cylinders and rings are now nicely seated, also you running a pretty much non existent exhaust system then?? Mine was dynoed with two silencers and full length system to the rear in 2.5" mandrel stainless. Still really need that top half of my header making and nice camshaft!

Wow finally getting down to some porting work!! You finally catching the N/A bug haha!

Looks good so far try not to mess up the seats too much but stick with a nice rough finish on the intake maybe even a little rougher, you can blend it in from the intake which make sure you get a nice smooth and even finish inside as well then start to make it rougher as you get to the intake port mouth then from inside the ports nice and rough helps to keep the fuel atomized and also to slow it down a little to get into the valves nicely, I also put a nice roughed up finish on the intake valve as well this seems to work really nicely on all my engines, all I did was put all the valves on a lathe and use a heavy duty grinding stone that you'd use on a drill and as the valve spins just very carefully run up and down the valve head and stem upto the guide area with it to give it a nice rough circular pattern all over.

Where the bottom of the valve seat is meeting the throat go over this area with something a little smoother though.

The exhaust ports and chambers it's more important to have a nice smooth shapes than being polished, polished is really only good for a full on race engine where it's going to get used in the first few 100miles once you go over this carbon sticks to anything after a while and it will soon buildup so on a non race engine that's not torn down every race it's not worth spending the time on.

The exhaust valve should be nice and smooth unlike the inlets and ports too, it's quite a big difference in reshaping the exhaust guide ramp and the tip of the guide, if you can get some SI valve bronze guides in the stock ones don't last long with uprated cams and higher revs.

unshroud around the valve heads as much as you can and blend the chamber roofs flush with the valve seats this require very steady hands and some blanking valves to protect the seat surfaces.

Top it off with a final head skim you can take it right down to the wear markers on the head surface and if you want an extra .5mm further but I tend to save a little for future head skims from general refurbing later on.

Fuck yeah! How was the headgasket, btw?

The head gasket was as bad as i hoped, but the head and the block look great. You can see some odd sealing around the water jackets.

Rich, youve probably written that same thing time and time again, thank you for writing it one more time for me.

P.S. what are you matching the inlet port mouths too? the gasket or the intake manifold?

have you done any work to the inside of the intake manifold? I found with my one there was room for improvement, first of which was to bellmouth the intake side that sits next to the carbs or port match them to the gaskets at minimum there is room for improvement there, then a nice smooth finish using the drum rolls getting rougher as it nears the heads inlet ports, the inlet ports should be matched to the inlet manifold, put manifold on with carbs off and use spray paint to mark the areas that stick out or racing blue spray if you can find it. It's important to keep the shape nice and flowing and not create odd angles, so as the inlet manifold tranistions to the head inlet ports make sure your not just opening up the first few mm to match it but go right into the port and create a proper bend, but obviously don't go too mad or you might go too far and go through something, there is plenty of meat though as you've seen from my recent head mine's way more hogged out than yours at the moment I think they measure about 40/41mm as that's the bore size of the carbs little point going smaller with my bigger valves!!

http://youtu.be/r2D3n9PXuy0

Here you go, Ryan.

Thanks gio!

Also rich, im matching the ports for the inlet manifold im currently running. I left the intake gasket on, so i cab see exactly where my inlet manifold was resting. I do believe my inlet manifold is kinda weird, but You can kinda see it in the pictures how the intake ports arent exactly concentric. But pretty round. Definitely matching the inlet manifold though

do you guys think with my pistons and the extra lift that I'll have piston to valve clearance issues if i shave the head down all the way? Or should I just try and shave down the minimum necessary. 89T, what you think? I know your setup is the closest to mine (it was the inspiration for mine!)

If it helps at all, I'm going with 10:1 pistons; and head is shaved down .030"

If you stick the head back on without the gasket and put the belt back on and turn over by hand if you make contact you know you won't have enough room, if it clears then you'll be fine as the H/G is a good 1.5mm thick so you should be safe for at least .5mm maybe 1mm, most accurate way would be to plastigauge the tops of the pistons to find out exactly how close they get and where they might contact.

My head is not milled, 10.5:1 compression pistons and the bisi 2.4 turbo race cam that has huge lift. I did not clearance them but I do know it is now an interference motor.

the pistons are 83mm flat top JE pistons with valve reliefs.

un-motivated!

someone make me an offer i just could not say no to.

3GR

are they just off the shelf JE???

My cam has 11mm of lift. And my pistons are pretty tall... Here is a reminder picture to give everyone an idea

Without hg

With hg

Last edited by hondalude86; 04-21-2012 at 03:43 PM.

Any more pics on new headwork?

un-motivated!

someone make me an offer i just could not say no to.

3GR

Those are from the bisimoto 2.4 turbo race cam.

un-motivated!

someone make me an offer i just could not say no to.

3GR

are those JE off the shelf for A20 or B18 ls? if for A20 what's the CR ratio meant to be? and do they fit onto stock honda rods? and have you got a part number could be interested in a set if they can do them with blank crowns or with a nice flat crown with reliefs cut. Don't suppose you took any pics of them?

I got them from a member a long time ago, I never wrote down or posted the part number. they are off the shelf 83mm b18 a/b pistons . You have to change or up grade rods to a stock b18a or eagle H-beam. I would imagine that the rods and pistons assembled are the same length as the stock a20's so the compression ratio should be as advertised. I am not sure if I do have any pics. I will look.

un-motivated!

someone make me an offer i just could not say no to.

3GR

That would only be true if the combustion chambers were the same size as well, and I doubt they are. I know the A20 chambers are about 48cc. Don't know about the B18 chambers. I have a spreadsheet for calculating A20 compression ratios though, so if we knew what the dome volume on the pistons was I could give you a pretty close estimate.

C|

mine are flat top's... hmm

un-motivated!

someone make me an offer i just could not say no to.

3GR

Bookmarks